The Importance of Tank Surface Smoothness

Tanks used in various industries such as pharmaceuticals, food, and beverages play a crucial role, and the smoothness of their surfaces is of great significance. The surface smoothness affects the ease of cleaning, and tanks with smoother surfaces, characterized by a lower Ra value (Roughness Average), make cleaning easier and leave no residues. Conversely, tanks with rougher surfaces, indicated by higher Ra values, are harder to clean and are more prone to retaining food particles and microorganisms. Therefore, tanks should have easily cleanable surfaces to comply with Good Manufacturing Practices (GMP) standards.

Here are some key points to consider:

1.What is Surface Roughness?

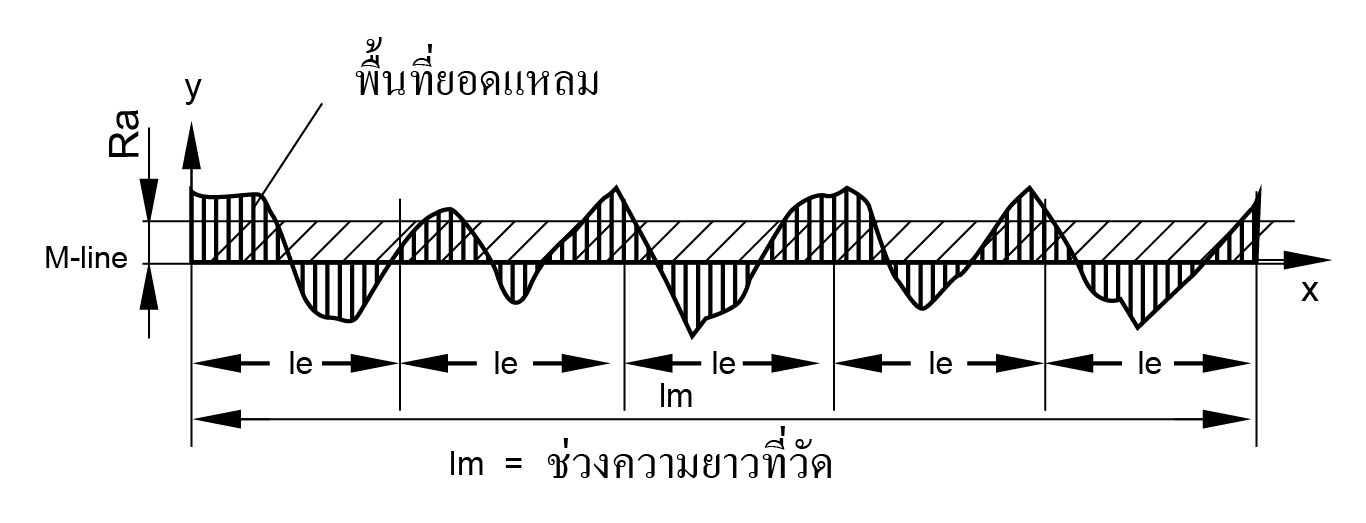

Surface roughness is a measurement of the texture of a metal's surface, such as Stainless Steel. It is assessed by magnifying the surface to reveal tiny waves or irregularities. The most commonly used measurement for surface roughness is Roughness Average (Ra), which represents the average height of all the peaks and valleys on the surface. The unit of measurement is in microns. A higher Ra value indicates a rougher surface, while a lower Ra value indicates a smoother one.

For food-grade tanks, the recommended Ra value should not exceed 0.8 microns. This smooth surface helps reduce contamination and the buildup of food particles and microorganisms, making it easier to clean and sanitize. Rough surfaces with pits or scratches can trap residues and pose hygiene challenges.

2.Characteristics of a Good Tank Surface

The interior surface of tanks that come into contact with products should be smooth and free from scratches. Stainless steel is commonly used for its food-grade tanks, and the 2B finish is often preferred. The welds on the interior of the tank should also be smooth, with an Ra value not exceeding 0.8 microns.

3.Tank Surface Maintenance

3.1 During manufacturing, it's essential to protect the tank's surface with plastic film to prevent scratches during handling, rolling, and welding.

3.2 When the tank is ready for transport, careful packaging is required to prevent surface damage during shipping, lifting, and installation. Plastic wrapping or cushioning can help protect the tank's surface.

3.3 During usage, it's crucial to clean the tank immediately after use to prevent residues from hardening and adhering to the surface. Extra care should be taken to avoid introducing materials that could scratch the tank's surface.

3.4 Preventive maintenance should be performed regularly. Inspect the tank's surface and welds inside, particularly in areas that come into contact with the product. Conduct tests like Penetrant Testing (PT) annually to identify pitting and address any issues before they worsen.

In conclusion, maintaining a smooth surface on tanks used in the pharmaceutical, food, and beverage industries is essential for hygiene, cleanliness, and compliance with industry standards. Proper care and preventive maintenance ensure the longevity and safety of these tanks in the production process.