Effective Tank Cleaning and Its Impact on Longevity

The cleaning of tanks used in industries such as pharmaceuticals, food, and beverages is of paramount importance for overall production. Each tank should be systematically cleaned to prevent contamination and undesirable incidents. Here are some essential points to consider:

Did you know... What can happen if tanks are not cleaned properly?

Cleaning a tank is akin to washing dishes after a meal to prevent spoilage and rotting. If tanks are left uncleaned, various issues can arise, including:

- Product Residue: Some products can adhere to the tank's surface, forming stubborn deposits that are challenging to remove.

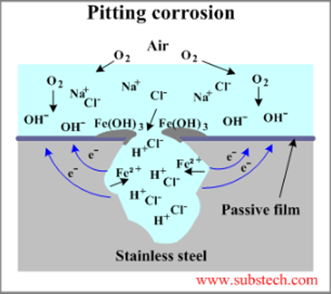

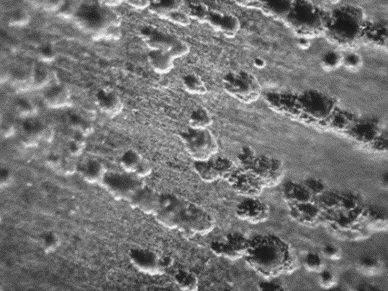

- Corrosion: Certain products, like those containing chloride, can corrode the tank's surface, leading to pitting when the chloride concentration increases.

- Crystallization: Some products, such as salt or sugar, can crystallize. If there are agitators or baffles on the tank's sides or bottom, these crystals may stick to them, potentially causing damage or leaks.

How to Design Tanks Effectively

To ensure effective tank cleaning, planning, and preparation should begin during the tank's design and manufacturing phases. If tanks are not appropriately designed or manufactured, issues may arise during operation. Key considerations include:

- Smooth Interior Surface: The tank's interior surface in contact with the product should be smooth, with no pockets or crevices that spray balls may not reach.

- Proper Sloping: The tank's bottom should be sloped adequately to ensure complete drainage, avoiding pockets where the product can accumulate.

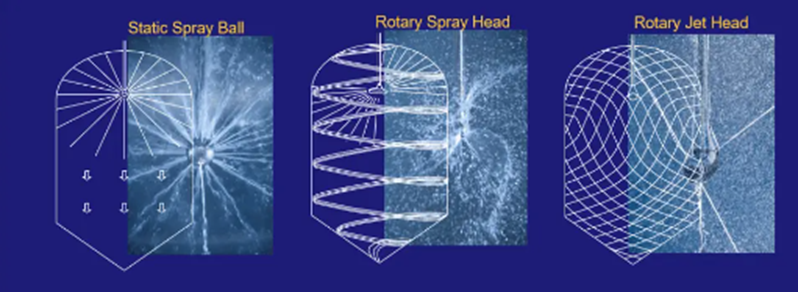

- Spray Ball Placement: Spray balls should be positioned strategically to cover the entire tank interior and eliminate dead spots.

- Surface Roughness Measurement: After manufacturing, the tank's surface should be measured for roughness. In food and beverage industries, the surface in contact with the product should not exceed a roughness value of 0.8 microns.

Effective Tank Cleaning Practices

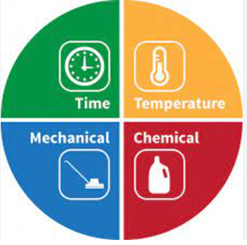

To achieve effective tank cleaning, several practices should be followed:

- Cleaning Frequency: Plan the cleaning frequency to align with production schedules. After using a tank, clean it immediately to minimize microbial growth and prevent stubborn residue buildup.

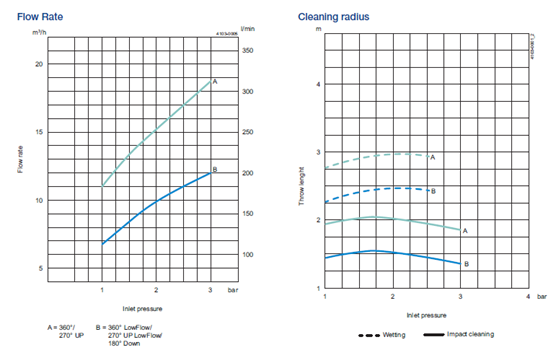

- Flow Rate and Pressure: Set appropriate flow rates and pressures for the Cleaning-in-Place (CIP) system to ensure that spray balls can perform their cleaning function effectively.

- Chemical Selection: Choose the right type and concentration of cleaning chemicals based on the product and tank material. Select suitable temperatures and cleaning durations for each step of the cleaning process.

Proper tank cleaning practices are essential for maintaining hygiene, ensuring product quality, and extending the service life of tanks in the pharmaceutical, food, and beverage industries. Careful planning, design, and adherence to cleaning protocols are key to achieving these goals.