What is Passivation and

How Does it Prevent Corrosion?

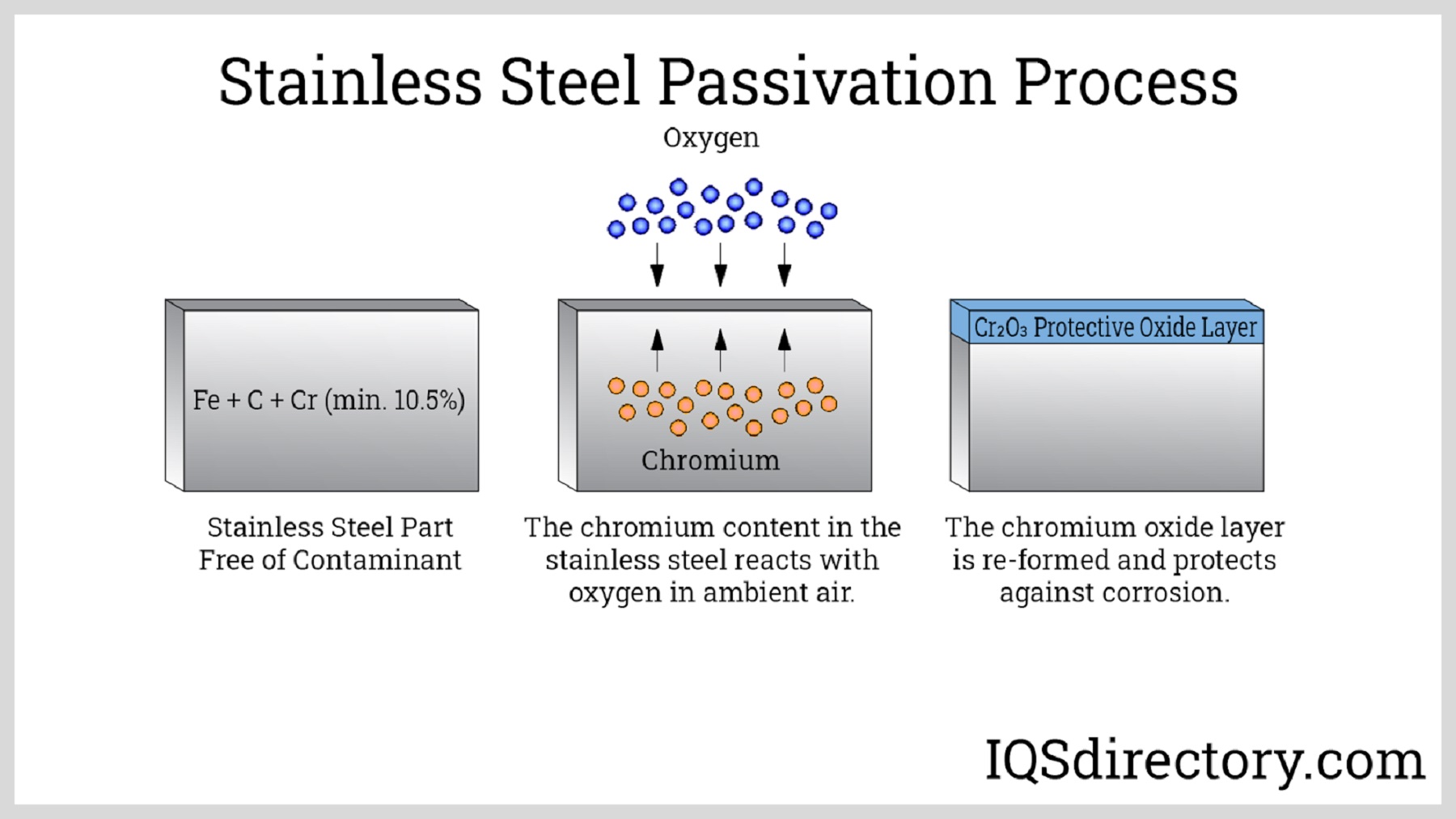

Passivation is a chemical process that stimulates the formation of a thin film, known as a Passive Film, to coat the surface of a workpiece. This film enhances resistance against corrosion.

Picture Ref.: https://www.iqsdirectory.com/articles/stainless-steel-tank.html

How Does Passivation Prevent Corrosion?

Normally, stainless steel surfaces develop a Passive Film spontaneously to resist corrosion. However, during manufacturing and usage, this film may be damaged by heat or fabrication processes. Prolonged contact with corrosive substances can also lead to gradual degradation of the Passive Film. Passivation is employed to restore the surface of stainless steel, making it corrosion-resistant once again.

During the Passivation process, chromium on the surface combines with oxygen in the air to form Chromium oxide, or the Passive Film, rapidly preventing corrosion on the stainless-steel surface.

Passivation Procedure

The Passivation process consists of three main steps:

1. Surface Cleaning:

- Clean the stainless-steel workpiece thoroughly by removing old film through abrasion, making the surface smooth.

- Eliminate dirt and oil residues, as they can react with nitric acid, hindering the passivation process.

- Clean with a solvent, followed by alkaline cleaning, and rinse with water.

2. Passivation:

Immerse the workpiece in an acid bath, or use a spray ball for tanks, to continuously circulate an acid solution and stimulate the formation of the Passive Film.

The type and concentration of acid depend on the stainless-steel grade:

- Austenitic stainless steel (series 300) and chromium content > 17%: Use 20% nitric acid at 50-60°C for 30 minutes.

- Stainless steel with chromium 12-14% and high carbon/chromium content (440 series): Use 20% nitric acid mixed with sodium dichromate at 50-60°C for 30 minutes.

- Precipitation hardening stainless steel: Use 50% nitric acid at 50-60°C for 30 minutes.

3. Rinsing:

- Immediately rinse the workpiece with water after the passivation process.

- Dry by allowing the water to drain for tanks or using other methods for different workpieces.

By following these steps, the passivation process helps maintain the corrosion resistance of stainless-steel surfaces, ensuring prolonged durability in various environments.

Passivation is a crucial step in maintaining the corrosion resistance of stainless steel. By understanding and implementing the passivation process, industries can ensure the longevity and reliability of stainless-steel components in various applications.